Our advanced manufacturing facility offers both a "material inclusive manufacture" and "free issue" sub-contract service.

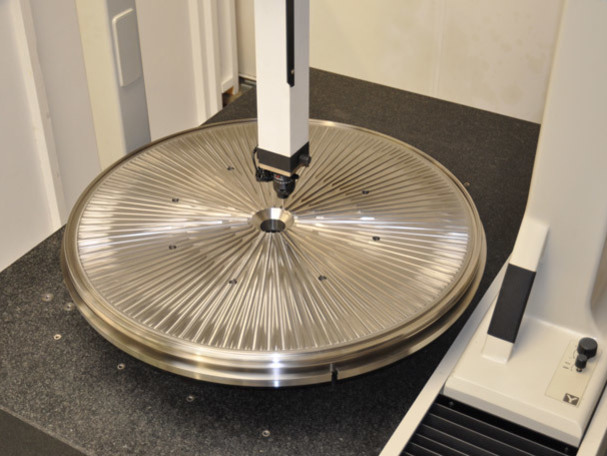

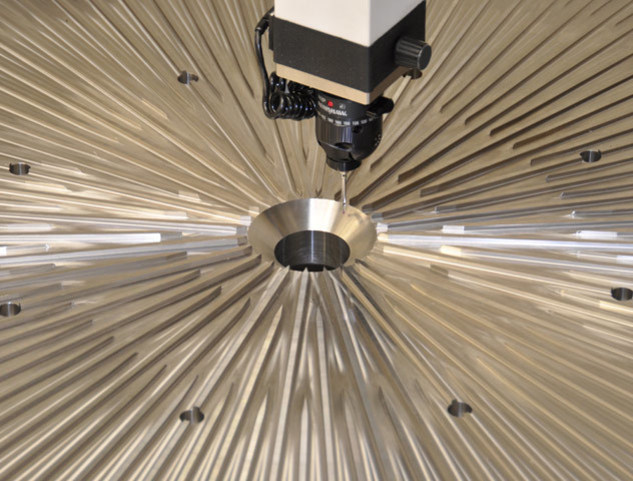

We use state-of-the-art 5-axis simultaneous machining centres, programmed offline from solid models created in our design office with the latest next generation 3D modelling systems.

Coupled with advanced cutting technology, we achieve fast production performance on sophisticated and difficult to machine stainless steels, nickel alloys and hardened tool steels of up to 3m diameter, 6m length, 2m³ and a maximum weight of 6 tonnes.

Intoco services markets that demand high quality products, fast delivery times and price competitiveness.

We are geared to respond to the very fast lead times that our customers demand, and with our immediate access to materials and our ability to accommodate 24/7 production, we can satisfy any critical or emergency delivery requirement.

In conjunction with the utilisation of efficient freight forwarders, we ensure that our customers receive their goods in the fastest possible time by road, sea or air.

MACHINE CAPACITY

Our manufacturing facility utilises state-of-the-art machine tools and programming software and this, coupled with advanced cutting technology, enables us to achieve very fast "floor to floor" production times over a vast array of component sizes and weights.

|

Machine |

Capacity |

|

Mazak |

|

|

Mazak Integrex 1850 Machining Centre |

Ø2300 - 2000³ |

|

Mazak Integrex E650 Twin Chuck Lathe |

Ø1100 x 2000 |

|

Mazak Integrex E410 Twin Chuck Lathe |

Ø500 x 1500 |

|

Mazak Integrex 400 Twin Chuck Lathe |

Ø500 x 1500 |

|

Mazak Slant Turn 50 Lathe |

Ø700 x 3000 |

|

Gildemaster |

|

|

Gildemester 600E Lathe with driven tooling |

Ø460 x 1000 |

|

Gildemester 600E Lathe with driven tooling |

Ø460 x 1000 |

|

Mori Seiki |

|

|

Mori Seiki SL7 Lathe |

Ø800 x 2000 |

|

Mori Seiki SL7 Lathe |

Ø800 x 2000 |

|

Mori Seiki SL7 Lathe |

Ø800 x 2000 |

|

DSG |

|

|

DSG 2413 Lathe |

Ø600 x 4000 |

|

DSG 3220 Lathe |

Ø700 x 7000 |

|

Maho |

|

|

Maho 1600S Machining Centre 3+2 Axis |

1600 x 800 x 800 |

|

Maho 1600S Machining Centre 3+2 Axis |

1600 x 800 x 800 |

|

Maho 1600S Machining Centre 3+2 Axis |

1600 x 800 x 800 |

|

Maho 1000S Machining Centre 3+2 Axis |

1000 x 700 x 600 |

|

Maho 1000S Machining Centre 3+2 Axis |

1000 x 700 x 600 |

|

Maho 1000S Machining Centre Twin Pallet 3+2 Axis |

1000 x 700 x 600 |

|

Machine |

Capacity |

|

Kearns Richards |

|

|

Kearns Richards SJ100 Horizontal Borer 3 Axis |

2000 x 2000 x 1500 |

|

Kearns Richards SJ100 Horizontal Borer 3 Axis |

2000 x 2000 x 1500 |

|

Webster & Bennett |

|

|

Webster & Bennett VTL 36"-RAM + Elevating Rail |

|

|

Webster & Bennett VTL 48"-RAM + Elevating Rail |

|

|

Webster & Bennett VTL 72"-RAM + Elevating Rail |

|

|

Webster & Bennett VTL 120"-RAM + Elevating Rail |

|

|

Huron |

|

|

Huron PU 660 Universal Mill |

|

|

Poreba |

|

|

Poreba CNC Lathe |

Ø500 x 6000 |

|

Thompson |

|

|

Thompson Surface Grinder |

48" x 15" Table |

|

Lumsden |

|

|

Lumsden Rotary Table Surface Grinder |

24" |

|

Lumsden Rotary Table Surface Grinder |

36" |

|

Lumsden Rotary Table Surface Grinder |

48" |

|

Lumsden Rotary Table Surface Grinder |

60" |

|

Herbert |

|

|

Deep Hole Borer |

Ø500(max) x 1300(max) |

|

Deep Hole Borer |

Ø500(max) x 1300(max) |

|

Deep Hole Borer |

Ø500(max) x 1300(max) |

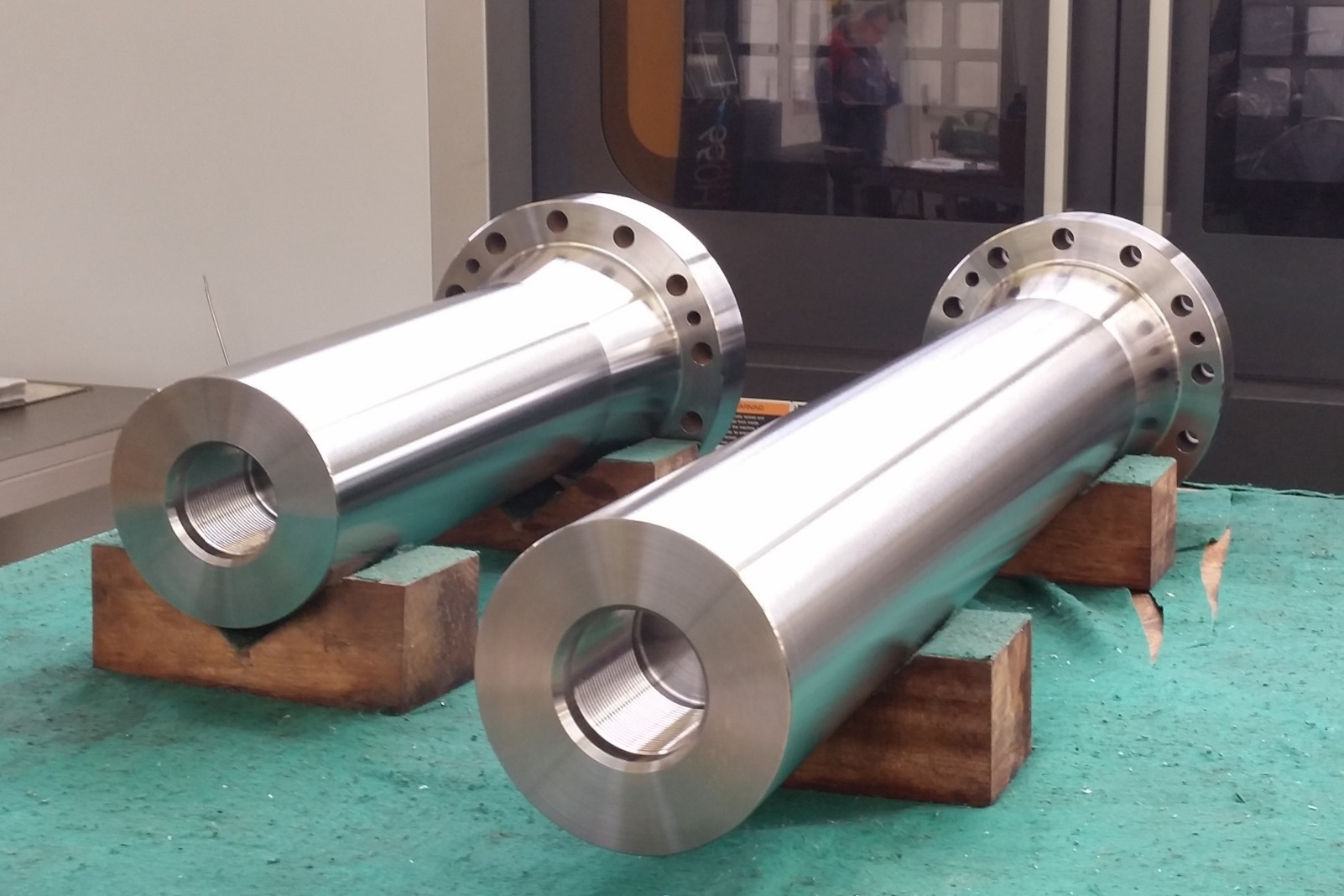

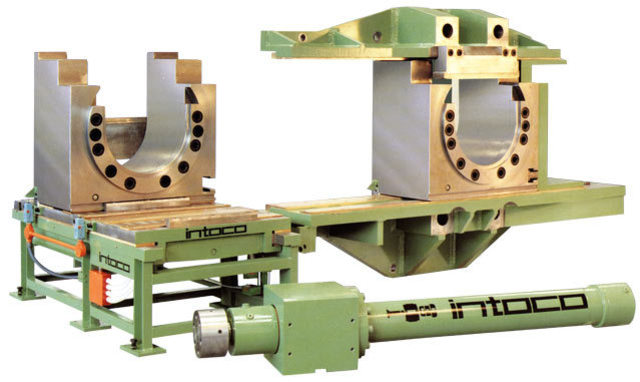

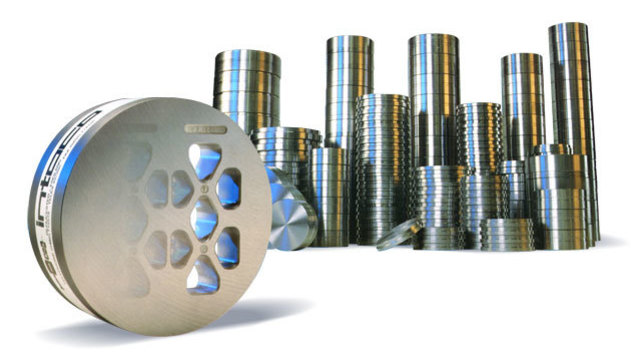

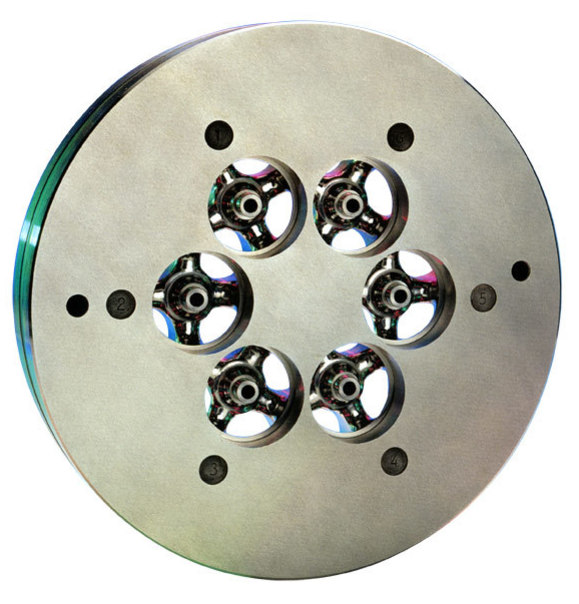

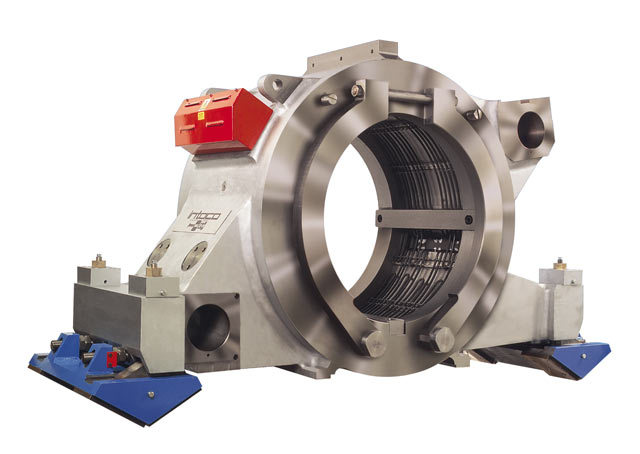

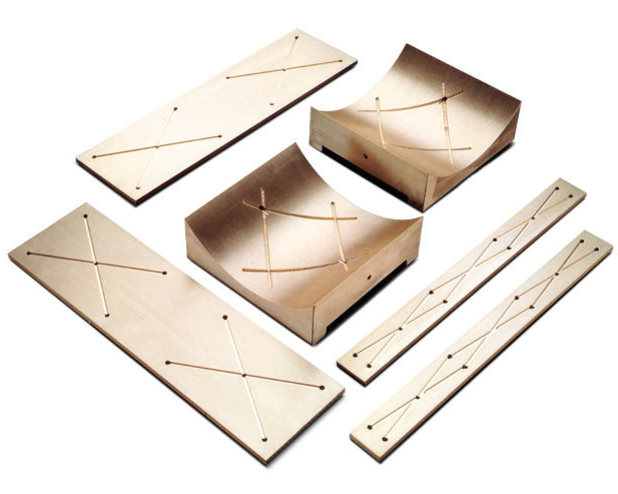

METAL EXTRUSION

In the highly competitive world of metal extrusion, Intoco offers a fast and flexible response in supplying 'On Demand' the consumable components essential for the uninterrupted operation of the extrusion press.

Since the company’s formation, Intoco has earned a formidable reputation as Europe’s leading independent supplier of high quality press components and tooling to both extruders and press manufacturers.

Container Assemblies

Container relining

Extrusion Stems

Fixed Dummy Blocks

Cleaning Discs

Die Rings and Bolsters

Shear Blades

Pressure Pads

Die and Backer Blanks

Main Cylinders

Platens

Columns and Nuts

Billet Loaders

Billet Transfer Systems

Container Housings

Die Shuffle Systems

Die Cassettes

Hydraulic Cylinders and Rams

Shear Cylinders

Phosphor Bronze Bushes

Phosphor Bronze Wearplates

Hot Work Toolsteel

INTOCO ADVANCED ENGINEERING FOR THE PHARMACEUTICAL INDUSTRY

Intoco manufactures components for the Pharmaceutical Industry up to Ø2300mm in fully certified low and zero Ferrite materials, Alloy C22 and Polypropylene, all under exacting criteria for isolation, cleanliness and non-contamination, coupled with a clean and controlled environment for the various processes including mechanical and electro-polishing of finished parts.

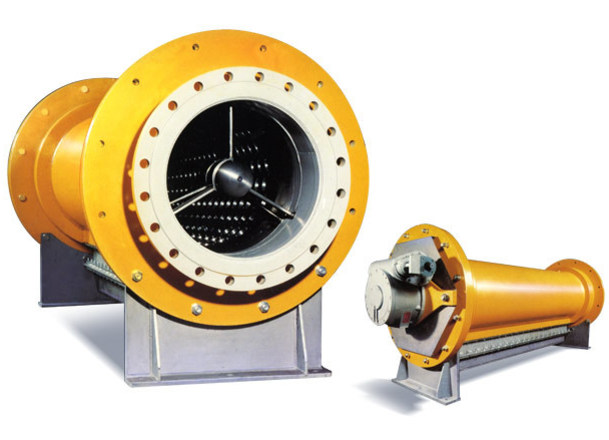

INTOCO ADVANCED ENGINEERING FOR THE ENERGY INDUSTRY

Manufacturing to all industries involved in the Energy sectors is of significant importance to Intoco.

We have made substantial investments over the past few years in very modern manufacturing equipment to allow us to serve the On-shore, Off-shore and Subsea Energy sectors (such as Oil & Gas, Petrochemical, Power-Generation, Renewable Green Energy i.e. Kinetic Energies such as Tidal Energy / Sea Swell Generation and Wind Farms, etc.).

Our forward planning and capability structure is very much geared around ensuring we have the ability to produce a complete cross-section of products, both large and small, to allow energy orientated companies and contractors to confidently use Intoco as a reliable out-sourcing partner for their critical product requirements.

Intoco's complete understanding and knowledge of complex raw materials such as Duplex Stainless steels, Nickel Alloys, etc., coupled with the ability to fabricate, finish machine, inspect, document, certify and distribute worldwide, enable buyers to procure products with absolute confidence, that they can be assured of “first-class fully traceable” products with “on-time” deliveries.

The next time you have an out-sourced product requirement, allow Intoco to tender for the part(s). With our professional approach to manufacturing, we are sure you will not be disappointed.

WANT MORE INFORMATION?

For more information on our Advanced Manufacturing facilities and services, or to request a quote, please contact our helpful sales team.